Hog Infeed Belt

When trees are cleaved in the sawmill, where I laboured, there were two possible destinations for what falls from them, as they change to planks, boards and other handy shapes. If it was free of bark and not specifically dust, a combination of belts that raced under the floors would deliver their scraps to a number of chippers. These chippers uniformly chop the wood waste, surprisingly, into chips, that in turn fill a steel bin large and high enough for a train car or semi-trailer truck to pass under and in turn be filled to then roll off to another dot of industry. These chips find a new day as paper, somewhere.

The remaining bark and specifically dust falls even lower, to a slow moving set of channels with chains running through them, these chains dragged thought their paths with a block that intersected the chain, creating a shovel. Dust and debris dragged along until it was heaved onto the fast moving, rubber Hog Infeed Belt. The tail spool of this belt almost touched the ground, a metre wide strip of rubber, zooming skyward, cutting through 3 floors where it ends and sprays its cargo into the Hog.

The Hog is a simple machine, a cylinder of perforated steel, on its side 6 metres long, 2 metres in diameter, made of 15 cm thick steel, spinning fast enough to turn whatever falls into it, with a roar, into cookie crumbs. This action is shrouded by a steel jacket with an impressive set of motors on each end of the cylinder to make it all happen.

The Hog Infeed Tail Spool, down below the Hog was currently being hidden by a giant, comical pile of debris, this mess, like the excited, expressive face of a child had a few interrelated parts. A static part, a slowly growing part and a active spraying part. There was some problem with one of the chains feeding this belt and the debris was falling into it off centre, then piling up and then flowing under Hog Infeed Belt and separating it from the Tail Spool which propelled it to its lofty deliver. This injection of debris was causing the fast, wide belt to wobble up and down with far more drama than necessary. Probably causing wear or some other problem that never fill the workers with any concern but torment the managers and the workers who one day wish to be managers.

My job, with others, was to get rid of this pile.

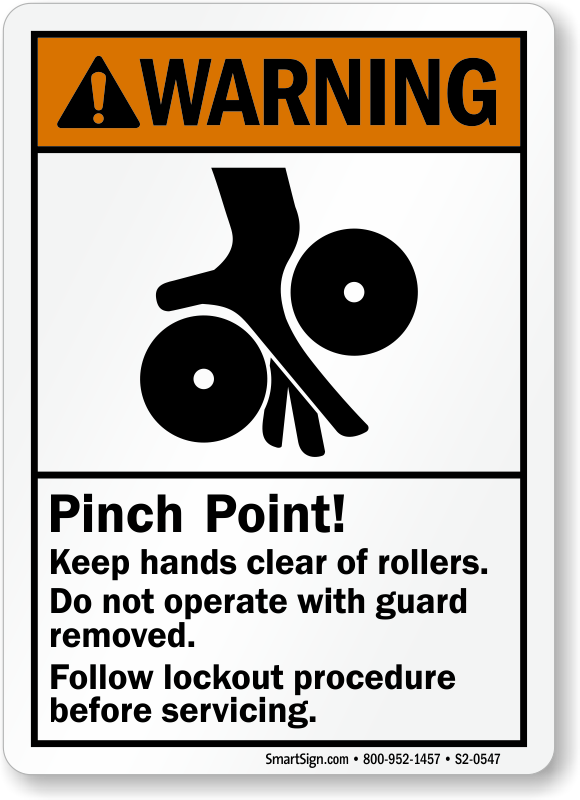

It was 05:00, tired and shovelling, from under the belt, crouched almost into a ball, I could dig and empty the contents of the shovel into a wheelbarrow beside the belt. My friend Jason was driving the wheelbarrow out into the rainy early morning. The shovelling was awkward. Dust was flying into my face. I placed my left leather gloved hand in front of my face while waiting for the wheelbarrow to return. This was a somewhat effective shield to the dust being kicked up by the bottom of the tail-spool and the belts rollers. I shifted my hand away from my face, just a bit, less debris hit it, I moved my arm again reducing my dusting.

In less than a breath, my body was instantly repositioned, where once my shoulders were parallel with the roller, there were now perpendicular, head and trunk twisted, the belt rushing over my head that was now pressed into my right shoulder, hand had touched the roller and that arm was on the other side of the roller, between the belt, the roller was now rotating like a drill under my left armpit, three thoughts, quickly in a row 1. my whole body will have to pass through for me to get out, 2. swearing 3. I have to get out now. Finding footing I pulled and freed the rolled arm. I was told I was screaming, even thought I remember articulating the seriousness of my predicament. Once freed, I sported a shaved left armpit, polished right knuckle, left elbow and tremors.